Junior INSA Services - Toulouse, France

While studying at INSA Toulouse, I was selected by the Junior Entreprise of my school to carry out my first engineering mission. During more than 4 months, I led alone a project commissioned by the French marketing company MIDISCOM. In regular contact with the client, I designed for them the mechanical structure of an olfactory diffuser. Carrying out this project in a completely autonomous way gave me a complete overview of how to manage a project from the elaboration of the technical specifications to its delivery.

Other images are not available to the public for privacy reasons.

Research Project

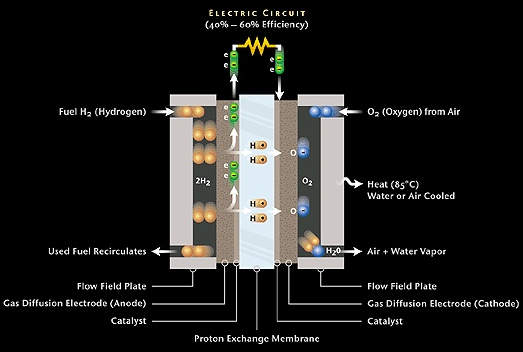

In the context of the electrification of land and air transport means, and especially the electrification of their propulsion system, Fuel Cells are one of the main contender for providing the required electrical energy. One of the most mature technology in this area that seems to step up is the Proton Exchange Membrane Fuel Cell (PEMFC).

Most of the time, the fuel cell itself is surrounded by thermal components, compressor, pumps, humidifier, valves, etc, mandatory for the operation of a PEMFC, The operation of this system is very related to the electrical power demand as well as the environmental conditions (air temperature, pressure, humidity). All these factors render this system a perfectly multiphysical system.

The Research Project consists of designing/preliminary sizing such a system. It can be challenging due to multiple interactions between the different physics involved in the system. Also, the choice of the operating point of the fuel cell is of utmost importance as is greatly determines the final sizing and performance of the whole system.

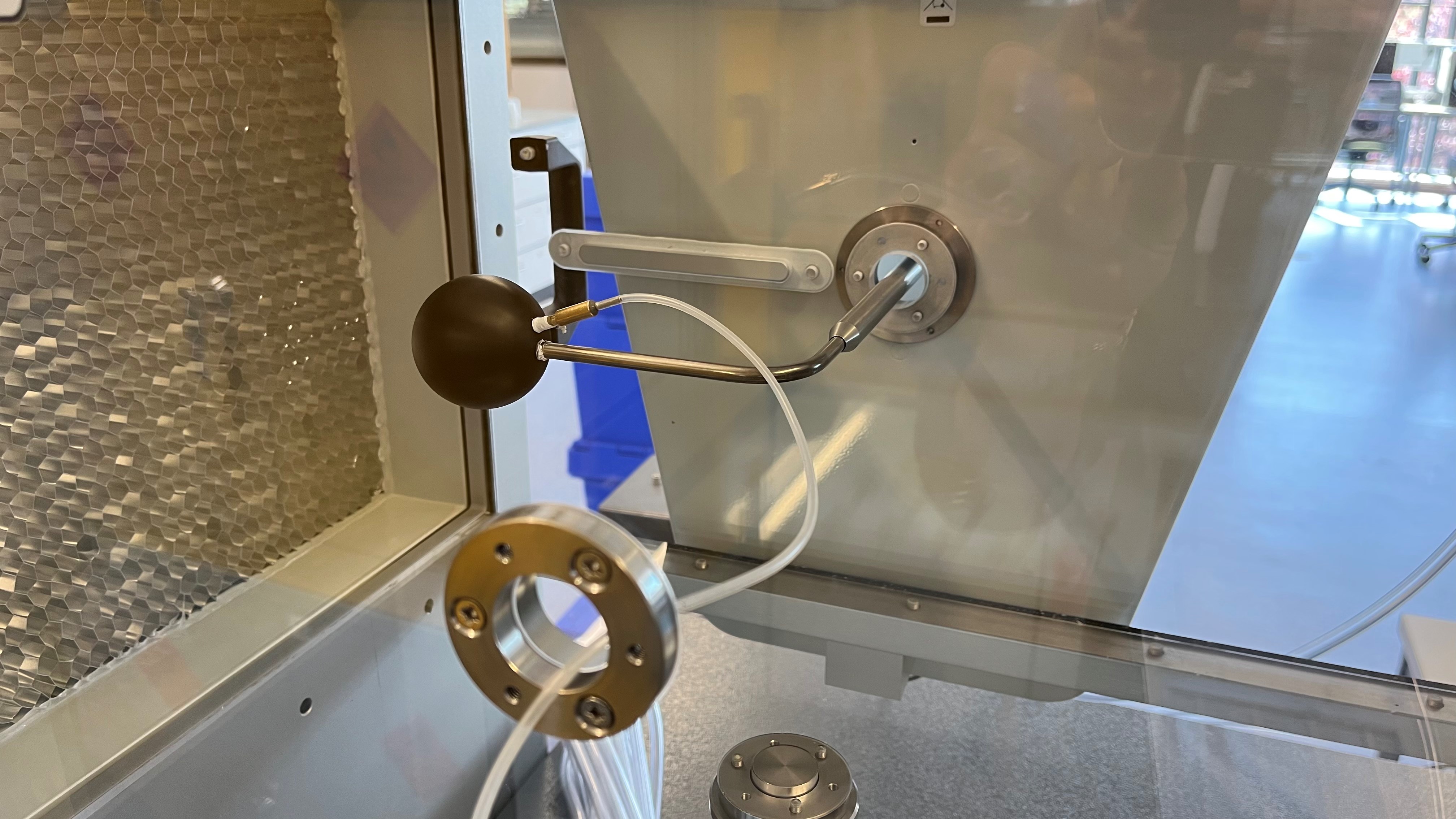

Independent

I am, in collaboration with a colleague, inventing, reaserching, developing, and implementating a new angle of attack measurement technology for light aircraft. Theory developed from the equations of fluid mechanics (self-taught). Application of flight mechanics. Design of CAD models using SOLIDWORKS, meshing and analysing data. Designing, dimensioning and tolerancing for machining prototypes. Behaviour modelling and analysis in a fluid environment using ANSYS Fluent. Project and management, create schedules, flow charts. Registration of Intellectual Property Rights.

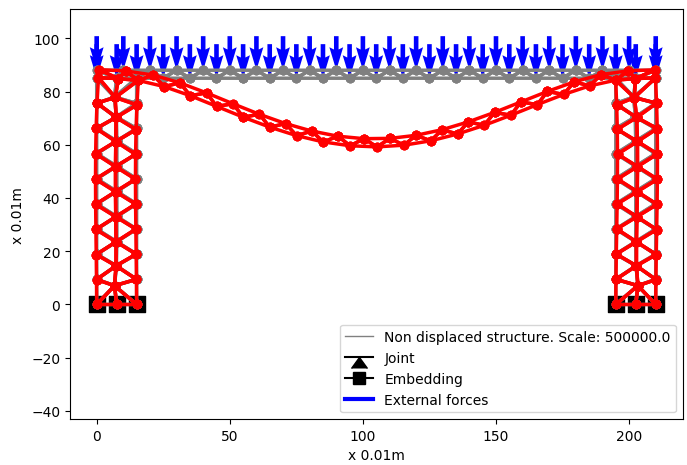

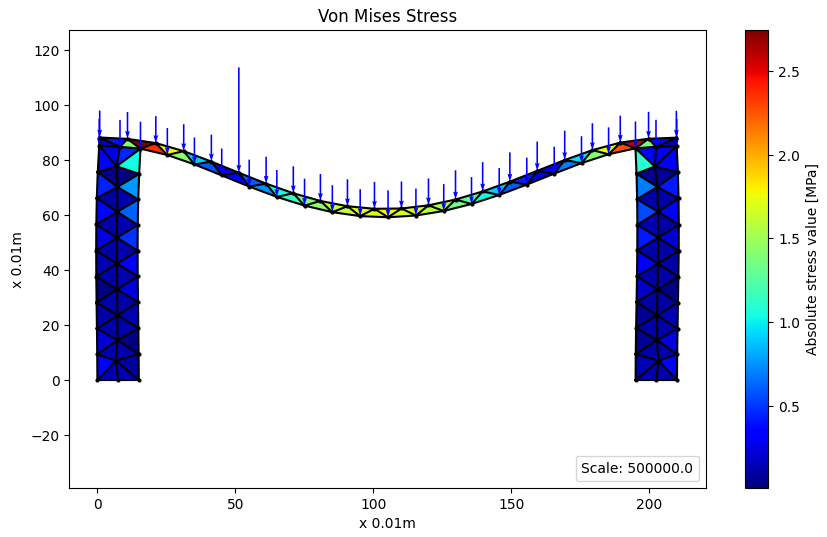

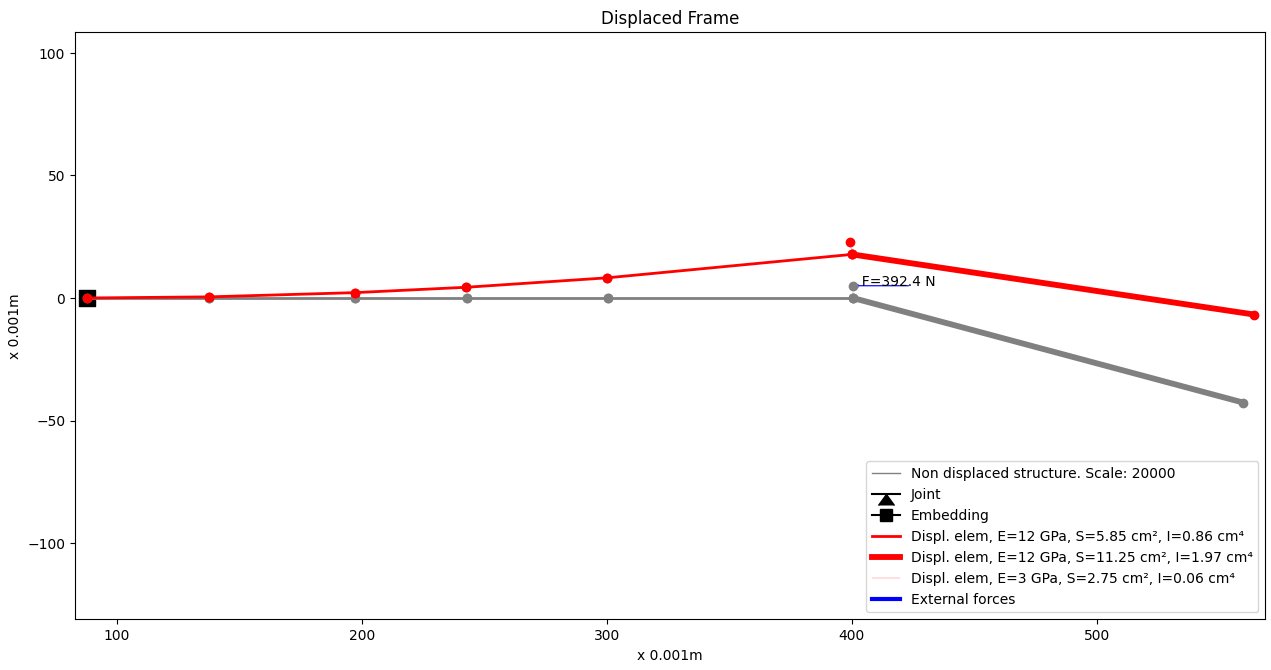

"Mechanical Sizing Theory" course optional personal project

I created a finite element sizing program. The aim of the FEM course in the third year of study was to teach us the theory of finite element analysis. To demonstrate our knowledge, we were asked to create a Python program using the theory studied to analyse the stresses and strains on a two-dimensional structure. The generalisation in three dimensions has little pedagogical interest once the 2D has been done.

Personal Project

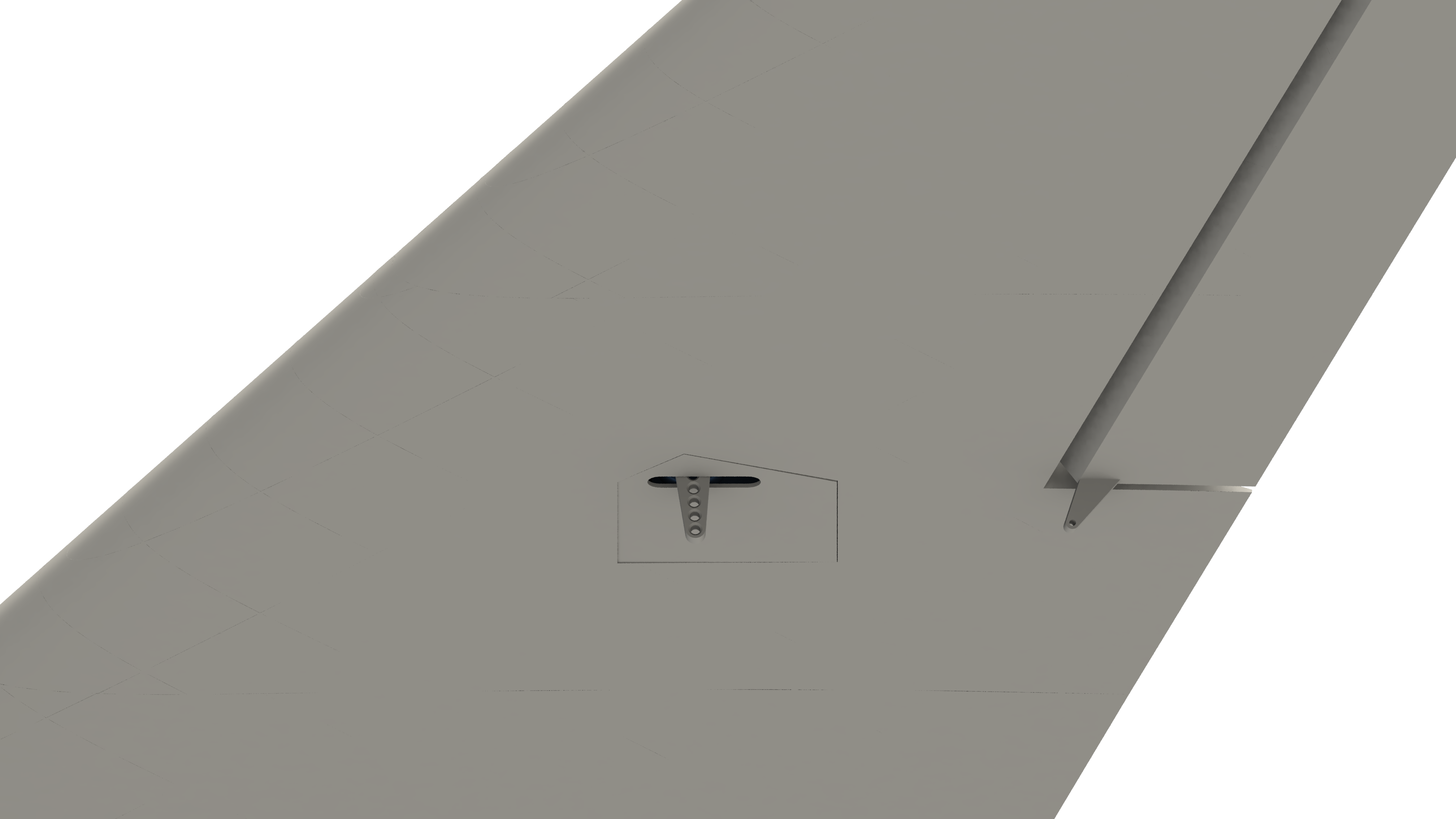

During the summer of 2021, I wanted to recreate the leading aircraft of the manufacturer AIRBUS: the A320-200. I wanted to make it look like a 1/27 scale model, but imagining it in such a way that it could be printed part by part by additive manufacturing of PLA in order to make it a RC plane. This required a lot of study and optimisation of the structure of the wings, fuselage and landing gear: combining lightness, ductility and robustness. This project was exciting because of the engineering required to make a plane that could actually fly.